Chrome Ore

COMMODITY: Chrome Ore

COMMON NAMES: Chromite, Chromium

FORMULA: FeCr2O4, Cr2O3

GRADES: 30%-32% 32%-34% 34%-36%

36%-38% 38%-40% 40%-42

SUPPLY CAPACITY: +5,000 MT/Monthly

SIZE: Lumpy and Concentrate

PACKING: Bulk in 20’FCL and Vessel

INSPECTION: Third

Party Inspection (SGS or Buyer’s preferred Lab)

PORT OF LOADING : Bandare Abbas, IRAN, (ShahidRajai Port)

Iranian Chrome Ore; Illuminating Industries, Inspiring Innovation

Chrome ore, a mineral defined by its lustrous brilliance and exceptional properties, exists in various forms and compositions. Among these is chromite, the primary source of chromium, which imparts chrome’s characteristic shine.

This ore is a natural mineral formation (lumpy, dark grey in colour) containing chromium in such compounds and concentrations as to make its commercial exploitation technically feasible and economically expedient.

Main Industry Usages: Powering Key Sectors with Resilience and Beauty

![]() Stainless Steel Production: This ore plays a crucial role in producing stainless steel. Chromium, derived from chrome ore, serves as a key ingredient in stainless steel alloys. Widely used across various industries—such as construction, automotive, aerospace, and kitchenware—stainless steel boasts corrosion resistance, durability, and aesthetic appeal. By incorporating this ore into stainless steel manufacturing processes, resulting alloys exhibit enhanced strength and greater resistance to tarnish and oxidation.

Stainless Steel Production: This ore plays a crucial role in producing stainless steel. Chromium, derived from chrome ore, serves as a key ingredient in stainless steel alloys. Widely used across various industries—such as construction, automotive, aerospace, and kitchenware—stainless steel boasts corrosion resistance, durability, and aesthetic appeal. By incorporating this ore into stainless steel manufacturing processes, resulting alloys exhibit enhanced strength and greater resistance to tarnish and oxidation.

![]() Alloy Production: This ore finds essential use in producing various alloys, including ferrochrome, which plays a vital role in the steel industry. Through smelting this ore with iron and carbon, ferrochrome imparts desirable properties to steel, such as high strength, wear resistance, and corrosion resistance. It is a key component in specialized steels for applications in construction, electrical equipment, and the automotive industry.

Alloy Production: This ore finds essential use in producing various alloys, including ferrochrome, which plays a vital role in the steel industry. Through smelting this ore with iron and carbon, ferrochrome imparts desirable properties to steel, such as high strength, wear resistance, and corrosion resistance. It is a key component in specialized steels for applications in construction, electrical equipment, and the automotive industry.

![]() Refractory Materials: In high-temperature applications, chrome ore is indispensable for producing refractory materials. These materials exhibit excellent heat resistance, thermal insulation, and chemical corrosion resistance. They are widely employed in constructing furnaces, kilns, and other heat-intensive industrial processes.

Refractory Materials: In high-temperature applications, chrome ore is indispensable for producing refractory materials. These materials exhibit excellent heat resistance, thermal insulation, and chemical corrosion resistance. They are widely employed in constructing furnaces, kilns, and other heat-intensive industrial processes.

![]() Foundry Applications: Foundries rely on this ore for mold and core production. Chrome ore-based sand additives offer high thermal stability, promote smooth casting surfaces, and enhance resistance to metal penetration. As a result, it remains an essential material in the foundry industry for manufacturing various metal components.

Foundry Applications: Foundries rely on this ore for mold and core production. Chrome ore-based sand additives offer high thermal stability, promote smooth casting surfaces, and enhance resistance to metal penetration. As a result, it remains an essential material in the foundry industry for manufacturing various metal components.

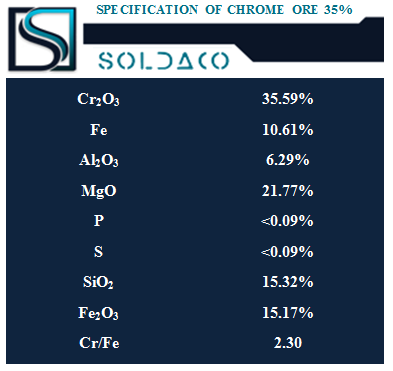

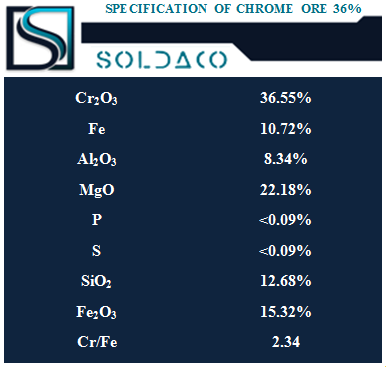

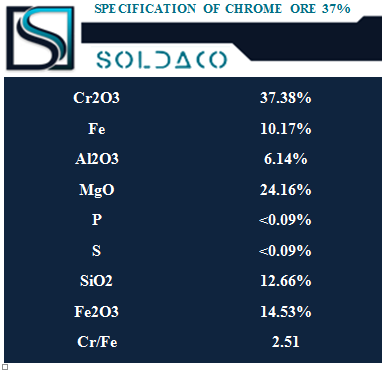

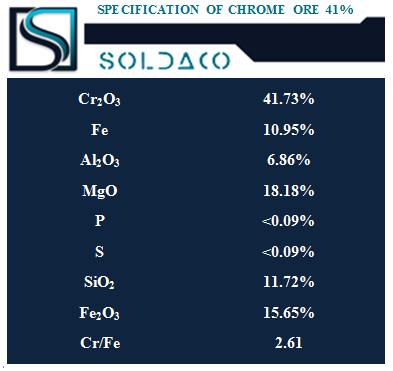

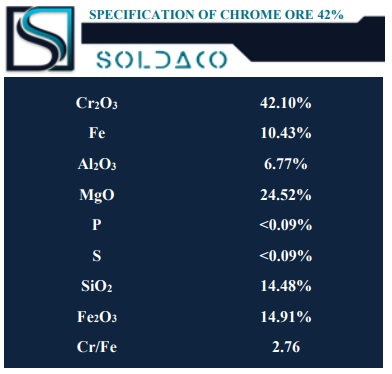

Chrome Ore Specification

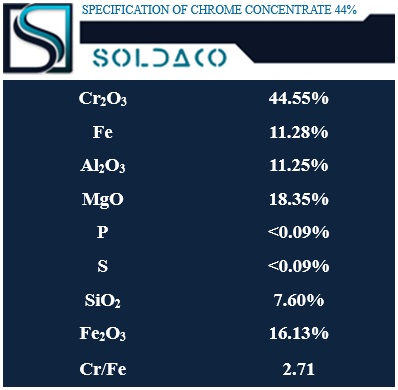

Chrome Concentrate

At SoldaCo, our commitment to excellence is exemplified through the supply of premium Chrome Ore to global markets. We uphold the highest standards of responsible sourcing, quality assurance, and sustainable practices, ensuring that each shipment of chrome embodies our dedication to industry advancement and positive impact.

Discover the brilliance and transformative potential of this mineral ore – a commodity that shape aesthetics, drive innovation, and underpin the essence of modernity. Contact us today to explore partnership opportunities and experience the exceptional quality and versatility of chromite, exclusively presented by SoldaCo.

Related Products

Contact Us For Chrome Ore Price or Any Inquiry

We welcome you to join our community and contact our team for any requirement.